Offset vs. Digital Sheets: How They’re Different

Printing is printing, right? Wrong.

Quality

Substrate quality has a significant impact on image quality. Brighter, smoother substrates yield more consistent adhesion, cleaner colors and higher print contrast. The quality of the substrate also significantly enhances the perceived value of digitally printed documents.

Key characteristics

The same characteristics that make a great offset substrate apply to digital substrates: formation, smoothness, and brightness. All three of these qualities play a role in superior print results and can’t be overlooked.

In addition, digital substrates are made to specific caliper and pre-defined moisture levels and are precision-cut to digital sheet sizes/rolls. These characteristics are built into the manufacturing specs for runnability and performance in digital presses. Digital substrates may also have a product-specific surface treatment for dry toner, liquid toner and inkjet applications. An example is Mohawk’s proprietary i-Tone treatment for digital substrates.

Shooting down some myths

In some shops it’s thought that cutting down parent-sized offset sheets for digital production saves money. This may be true in the short term, but in the long run it could end up costing you money.

If you guillotine your own substrates, you might be introducing contaminants into your digital press — dust and debris that could cause image quality defects and lead to premature replacement of your engine’s internal parts. Then you have waste and extra time and labor cost associated with the cutting. There’s the possibility that sheets won’t be cut square or won’t be properly separated from each other for feeding. And let’s not get started on the importance of grain direction for digital, particularly when finishing is involved!

Besides the money-saving myth, some printers contend they’re simply trying to match their stock across platforms. Mohawk offers digital products to match most of our offset grades for precisely this purpose. We can even offer you matching envelopes, for your most particular clients. It’s part of our commitment to provide papers and specialty substrates for all the ways you print.

Uniquely digital

There’s also an expanding world of substrates that are engineered only for digital. These help you offer your customers a limitless variety of printed products that typically represent higher margins for your bottom line. With print runs getting smaller, specialty substrates provide another way to add value and variety to what you’re producing … while increasing your profits.

The important thing to remember is that not all substrates are created equal … on purpose. Would you use thick litho paste inks on your flexo press? No way. Substrates are engineered and optimized with specific printing technology in mind, to get the best possible results on your digital press and the best return on your equipment investment.

Investing in the right materials for your press helps not only deliver the best results and helps you run a more efficient press room, but it will keep your customers coming back for more great quality printing.

Tips for Choosing the Right Sheets:

- All press sheets aren’t created equal. They’re designed for specific printing equipment.

- Digital-only substrates are made to precise caliper and moisture levels, and can have surface treatments for dry toner, liquid toner or inkjet applications.

- Risks posed by cutting down litho sheets to use in your digital press include: (1) Introducing contaminants into your equipment, (2) Extra cost — waste, time and labor, (3) Sheets not cut square or won’t easily separate, and (4) Grain direction might be wrong for finishing

- If you’re matching sheets across platforms, Mohawk makes digital products — even envelopes — that match most offset grades.

- Materials made only for digital — pre-converted forms, synthetics, pressure sesntive materials, magnetics — let you offer more value-added services for a bigger bottom line.

Production Notes

Offset Printing

A commonly used printing technique in which the inked image is transferred from a plate to a rubber blanket, then to the printing surface. When used in combination with the lithographic process, which is based on the repulsion of oil and water, the offset technique employs a flat (planographic) image carrier on which the image to be printed obtains ink from ink rollers, while the non-printing area attracts a water-based film (called "fountain solution"), keeping the non-printing areas ink-free.

Suggested Articles

The beauty of mail art is its low barrier to entry which gives anyone the ability to elevate the everyday to the extraordinary.

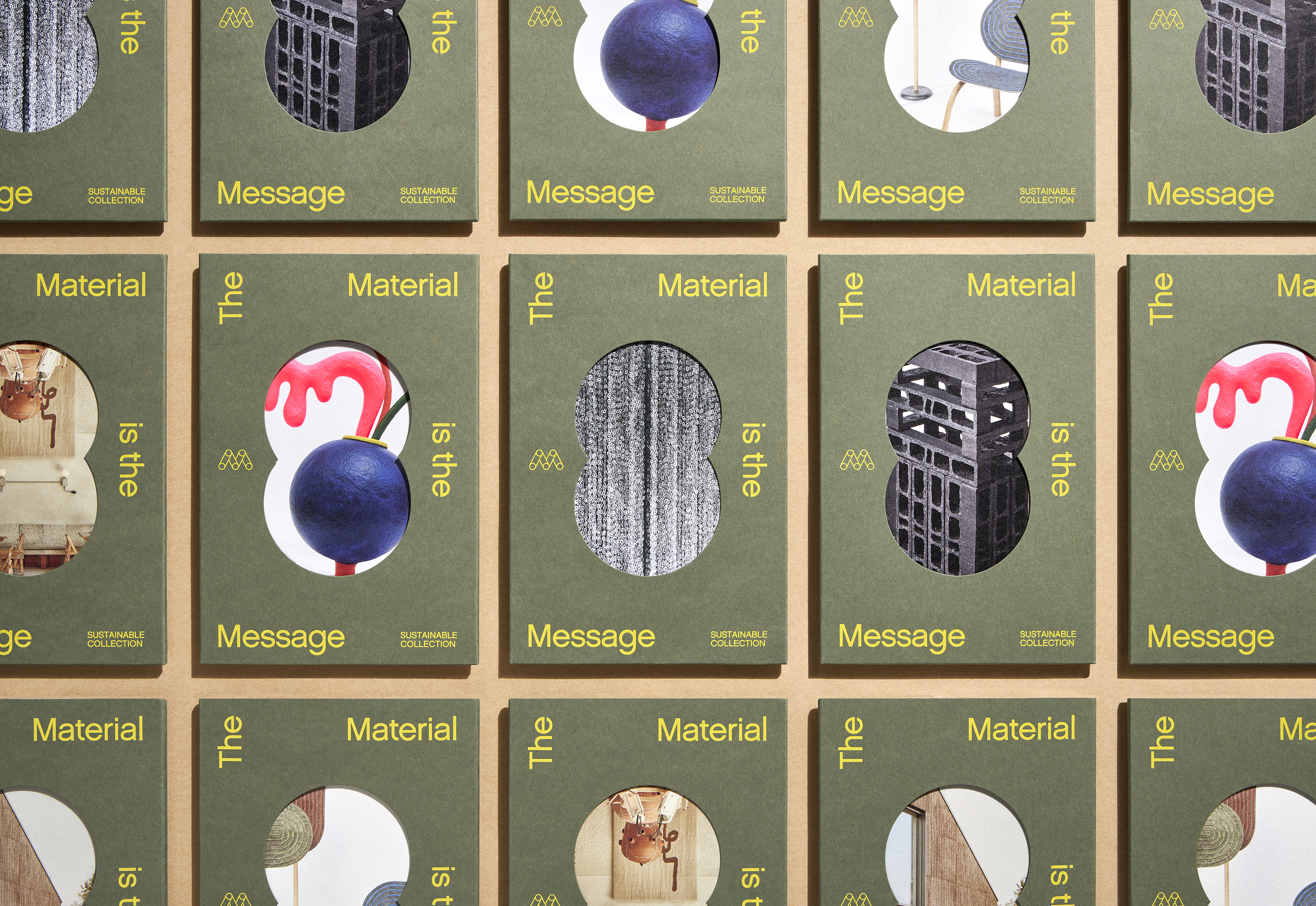

"The Material is the Message," tells the story of 6 different installations, dwellings, sculptures, objects, or other artifacts that are created using alternative materials or methods.

When COVID-19 hit the American economy and forced businesses to shutter in 2020, executive recruiter Kristy Hurt—like so many professionals—found herself on shaky ground.