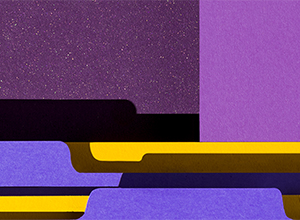

A carbon-neutral grass fiber—miscanthus embodies the resilience and potential of this remarkable biomass crop for pulp production.

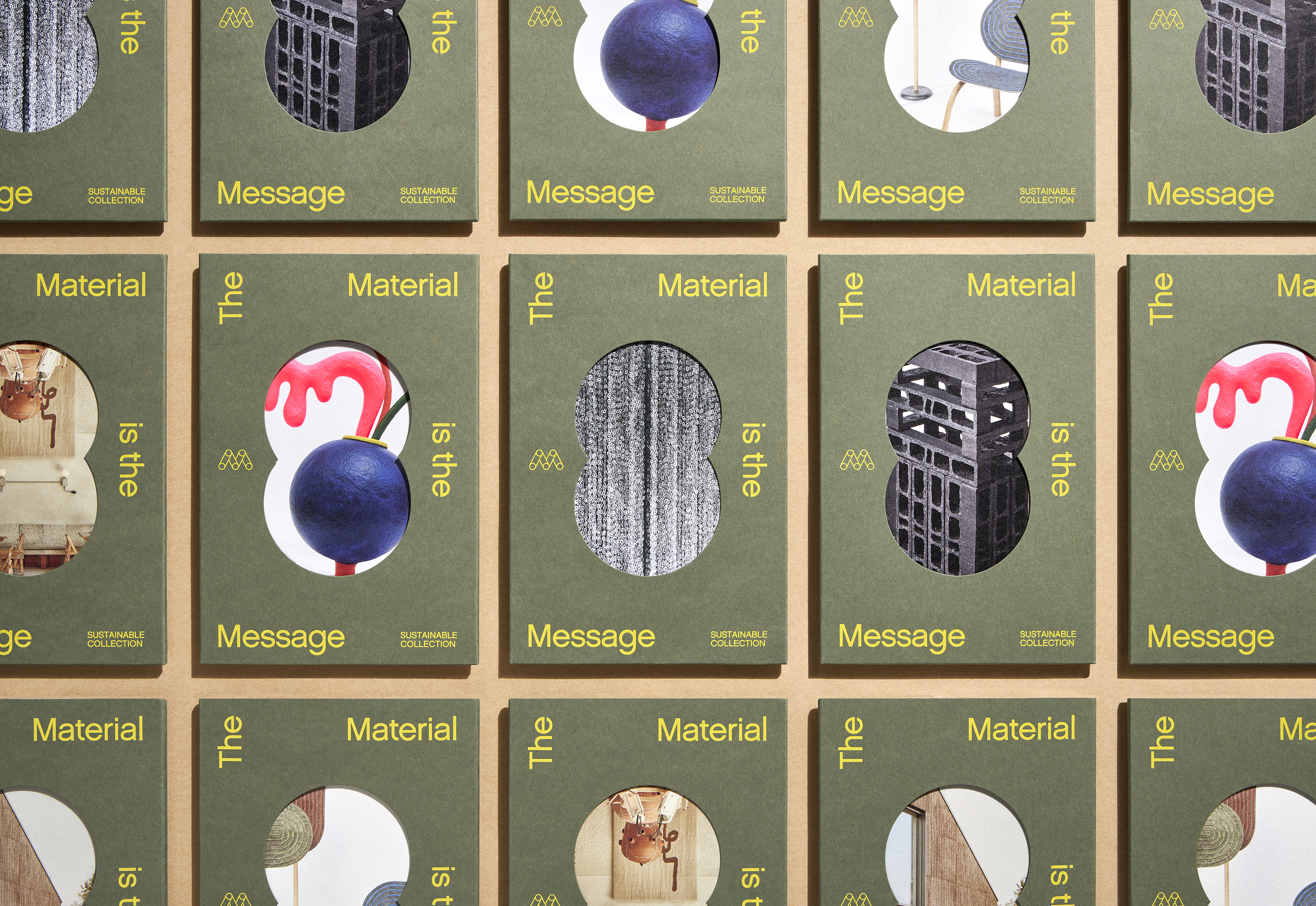

Sustainability with a Story

Mohawk Renewal

Hemp

Hemp grows rapidly, maturing in as quickly as 90 days. Turning hemp into pulp requires less chemicals, water, and energy than wood.