Looking Below The Surface

It’s obvious: Poor toner or ink adhesion can cost you time and money — even customers.

What a difference R&D makes

Only a few papers were designed for the early digital presses. The first HP Indigos required applying a pre-press treatment to the paper to ensure complete ink transfer and adhesion. This additional step of pre-treating papers, called Sapphire coating, was time consuming, expensive and reduced the paper’s shelf life dramatically.

Through a strategic R&D initiative in our labs, Mohawk engineered a proprietary surface treatment called i-Tone, which made possible digital cross-platform papers with superior transfer and adhesion of both dry toner and HP Electroink. Mohawk i-Tone digital papers offer better image transfer, better image durability and better image quality, consistently measuring 99% adhesion — compared to 80% or less for other papers. Result: increased uptime and a cleaner-running press.

An additional benefit of using i-Tone papers on the HP Indigo: Fewer “clicks” are required to clean blankets. This extends blanket life, saves wasted sheets, increases your productivity … and eliminates the issue of short shelf life.

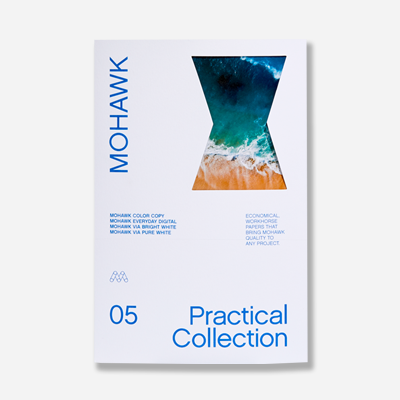

While i-Tone was originally developed for the HP Indigo (which use liquid inks and a lower transfer temperature), the treatment also enhances printability on any press using dry toner. Among the major digital presses, the Xerox iGen and Color Presses, the Kodak Nexpress, the Canon imagePRESS and the Konica Minolta presses use a dry toner/heat-based process.

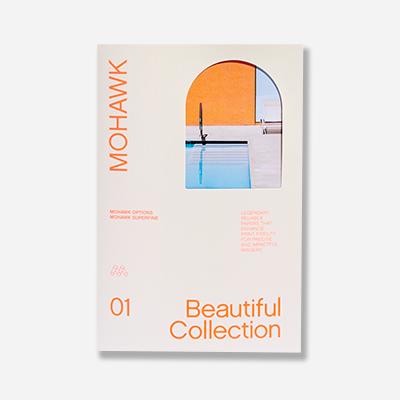

Grow your digital paper portfolio

Today, more print customers are looking for options in branded papers—papers that aren’t simply bright white and gloss coated. Mohawk i-Tone improves toner transfer and adhesion on textured papers such as Via Linen and Strathmore Script Pinstripe Laid. The precisely engineered surface chemistry of i-Tone papers has such an affinity for toner that it helps retain the toner in the low areas, or “valleys,” of the paper.

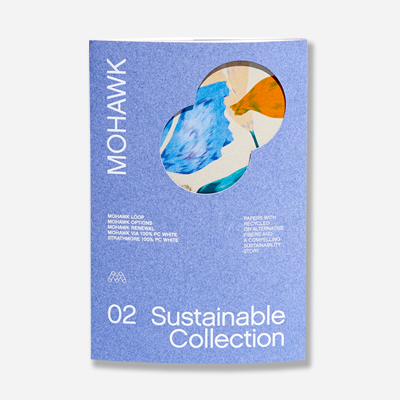

Unlike Sapphire-treated papers, i-Tone papers can also be used in secondary processes such as offset, UV coating and lamination. Another plus: The i-Tone process can be applied to other Mohawk papers as long as production minimums are met.

Digital printers who use i-Tone papers can reduce costs, eliminate shelf-life problems, and offer customers a wider range of high quality papers. Now you can present digital options to your customers through papers that truly carry their message with confidence.

For more information on i-Tone papers, contact your Mohawk sales representative.

Tips for Digital Additives:

- New technologies like Mohawk’s i-Tone surface chemistry offer superior transfer and adhesion of both toners and inks. And i-Tone works beautifully with textured papers, too.

- Besides improved print quality, benefits of i-Tone include lower costs, higher productivity and better shelf life.

- Mohawk papers with i-Tone chemistry can be used in secondary processes like offset, UV coating and lamination.

- The i-Tone process can be applied to other Mohawk papers, with a minimum order size.

Production Notes

i-Tone

Mohawk’s proprietary Digital with i-Tone surface has a unique affinity for both liquid and dry toners, offering breakthrough performance on HP Indigo presses and color digital production presses using dry toner. Mohawk’s i-Tone papers have exceptional transfer, adhesion and image durability on smooth and textured papers.

Suggested Articles

The beauty of mail art is its low barrier to entry which gives anyone the ability to elevate the everyday to the extraordinary.

Nothing is created in a vacuum. Our community—the always-evolving context of our physical, social, and emotional lives—has everything to do with how we make and view art.

Lead Brand Designer Katelyn Stetler reflects on Crane’s tradition of craftsmanship, and introduces 77 timeless designs to 2019’s holiday capsule collection.