The Evolution of Cotton Paper

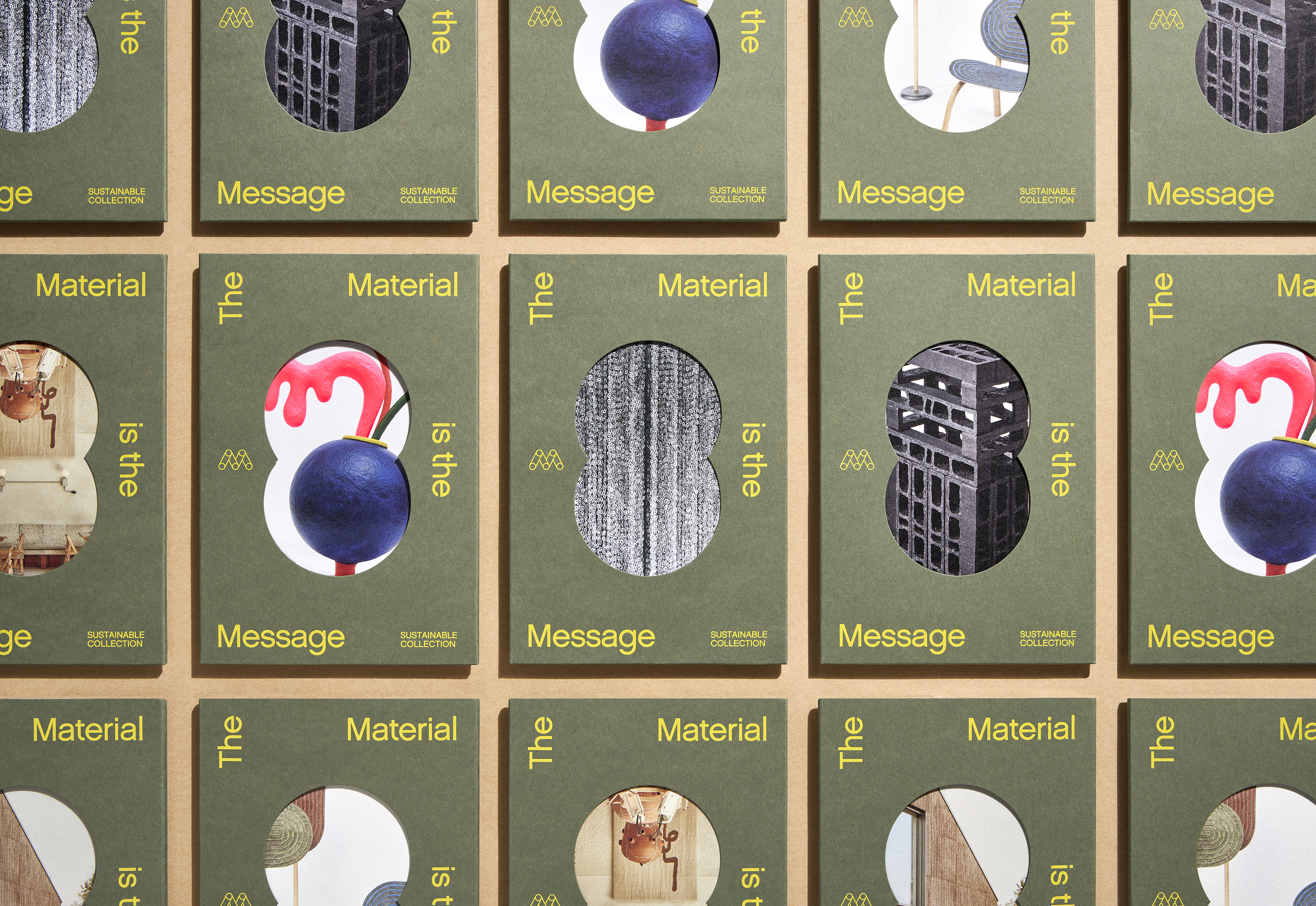

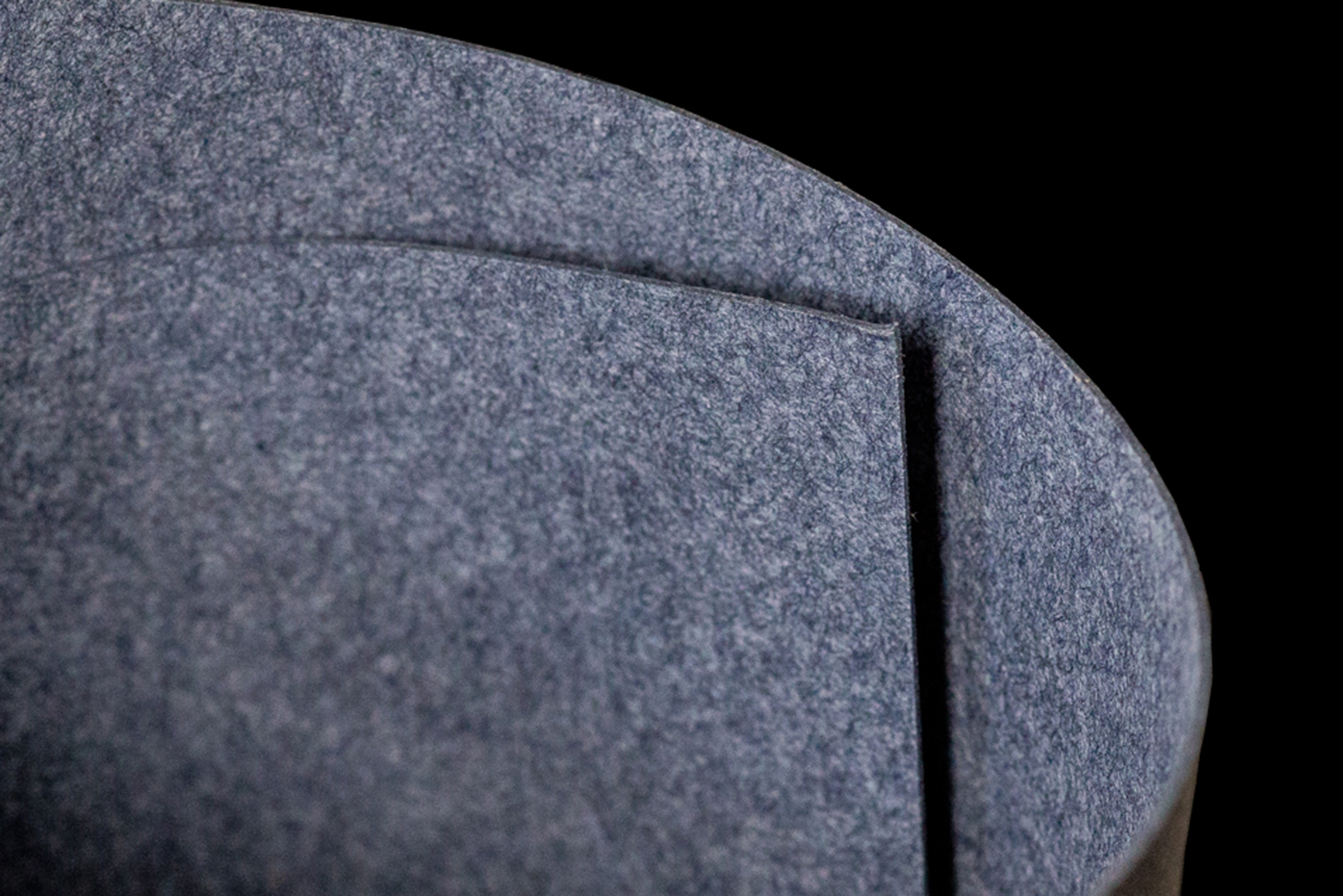

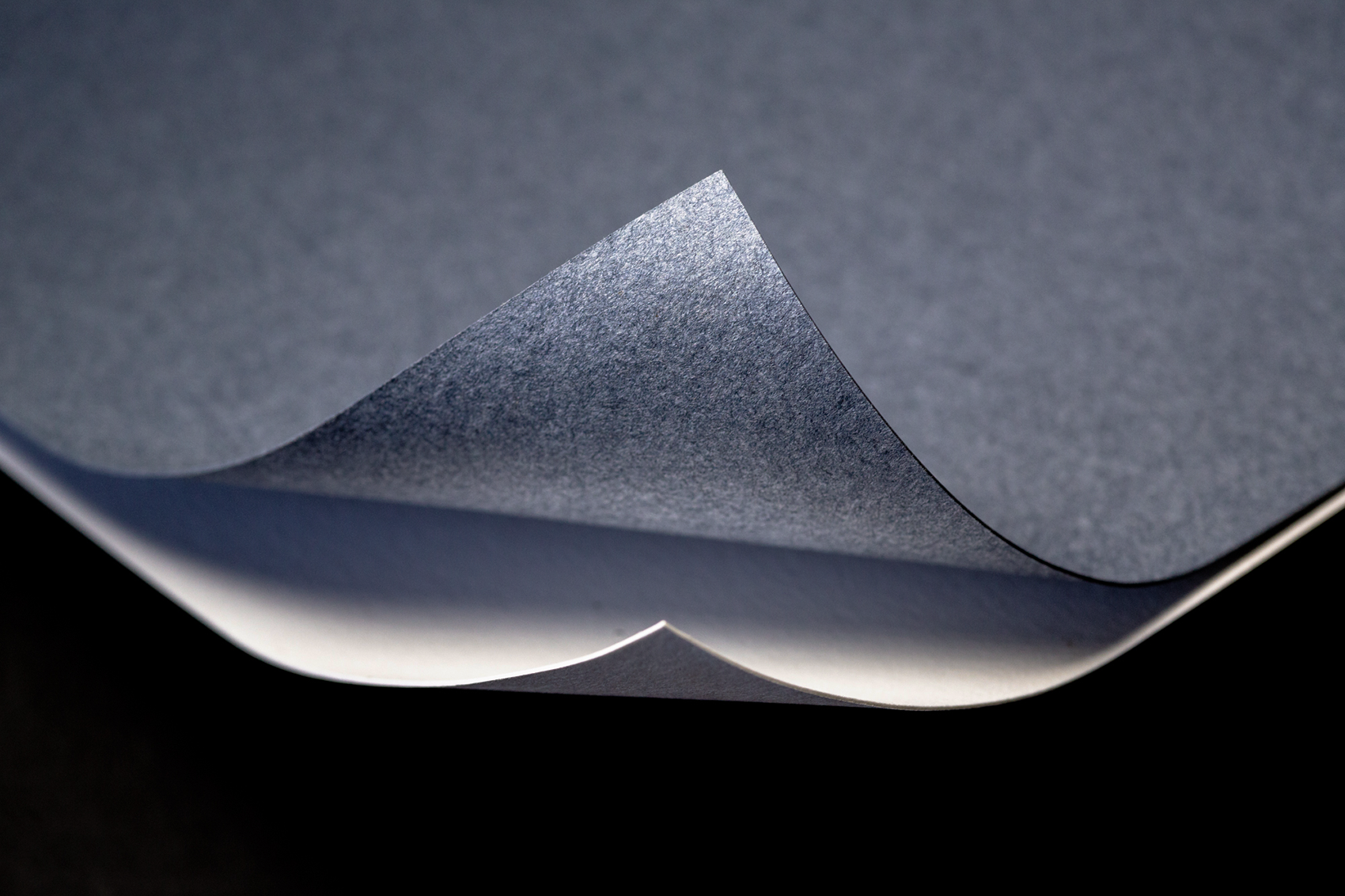

For centuries, cotton textile waste was recycled to make paper. Strong, yet soft, these cotton fibers make beautiful paper.

From paper made the same way it was in the 1800s to a paper being made from fast fashion scraps today, cotton paper is as archaic as it is innovative.

Suggested Articles

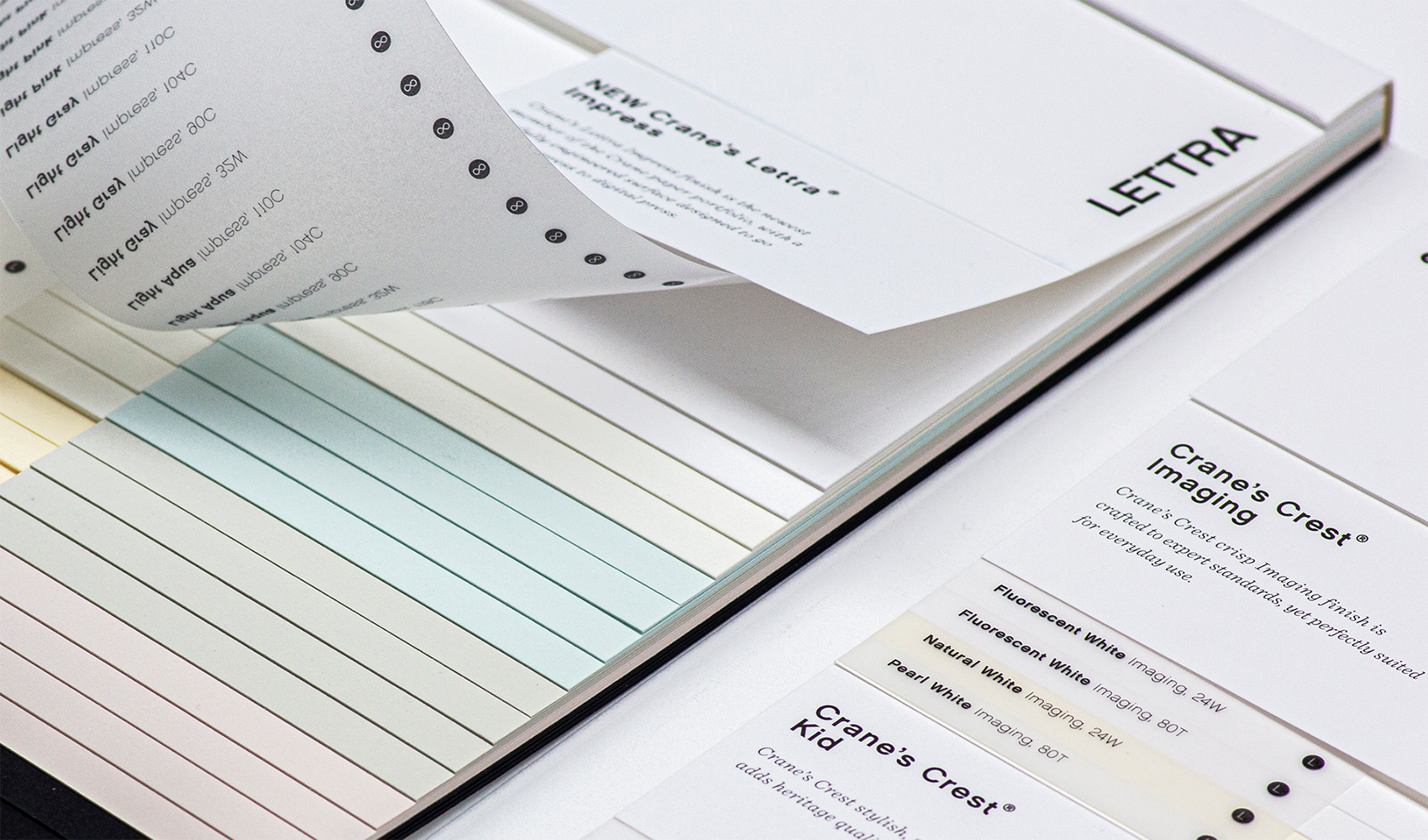

Behind every great partnership is a story, and in 2018 we began a new chapter with the acquisition of Crane Stationery.

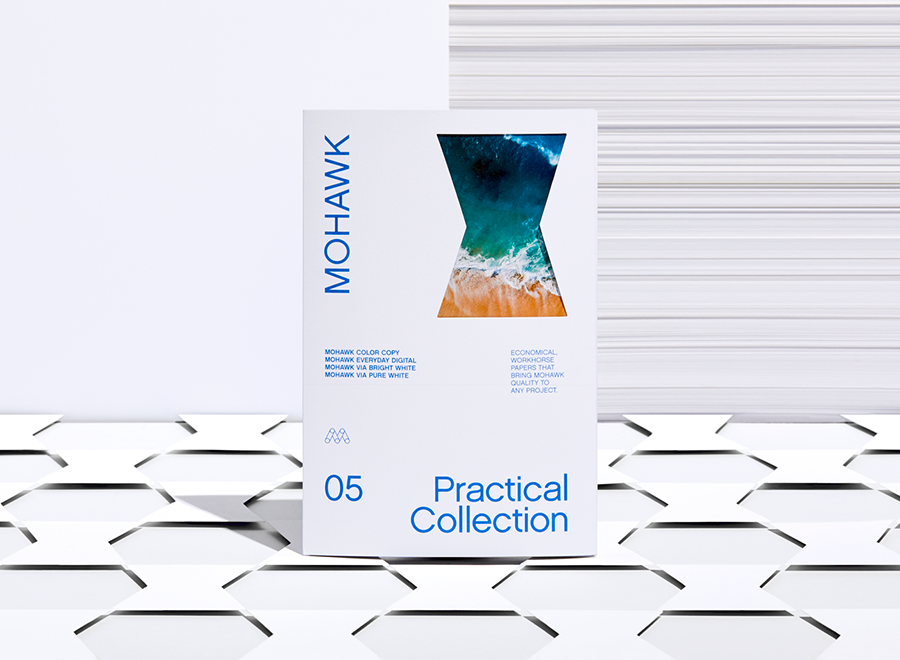

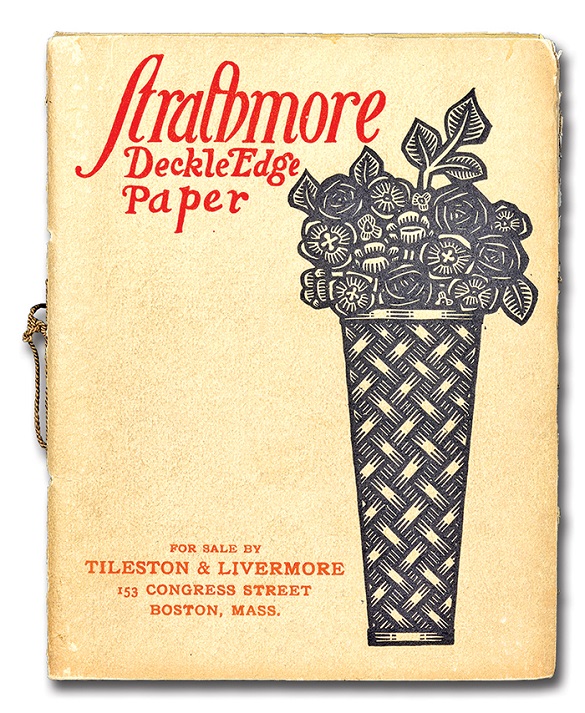

In 2014, Mohawk stumbled upon a paper holy grail: a collection of samples, swatchbooks and sales guides boxed up in a warehouse, all but forgotten.

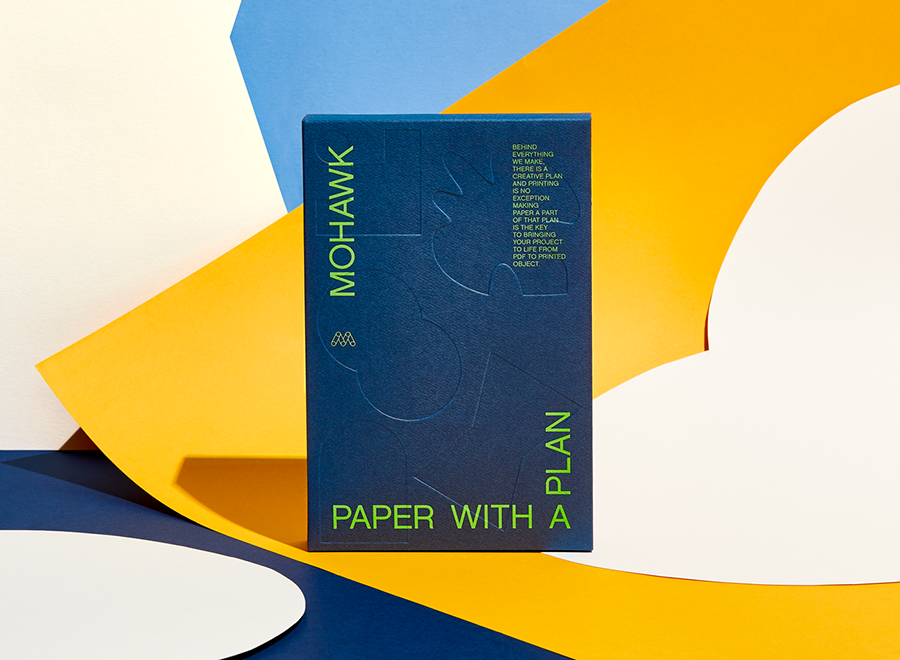

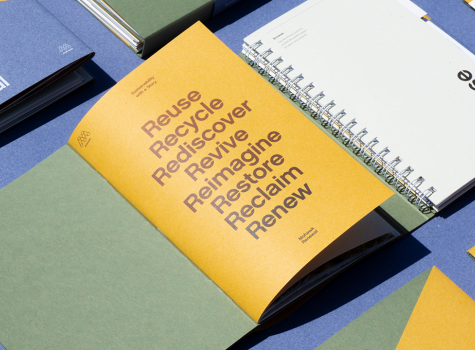

The moment you pick up a Mohawk Renewal swatchbook, the story begins to unfold.